Overview

Transforming a design CAD model into a geometry that is appropriate for simulation requires a different focus than CAD systems generally provide. The ability to quickly identify and remove unneeded features in the model is a very important capability. Augmentation of the model to support ease of mesh generation as well as specification of analysis attributes (boundary conditions etc.) for the simulation is also critical. Support for both mixed dimension models and non-manifold geometry (often not well supported in CAD sytems) is also needed. SimModeler provides all of these capabilites in an easy to use application.

In addition to working with CAD geometry, SimModeler is also designed to work with discrete geometry (mesh-based geometry from STL or other sources). Tools are available to detect issues with the mesh and perform local and global improvement and repair operations. Full boolean capabilities are available to union individual parts.

Capabilities:

- Simplify models for simulation. Remove parts from assemblies, model entities from parts, simplify surfaces

- Add far field regions for flow analysis

- Modify model geometry (add model edges/faces) for meshing or solver analysis application

- Fix assembly misalignments

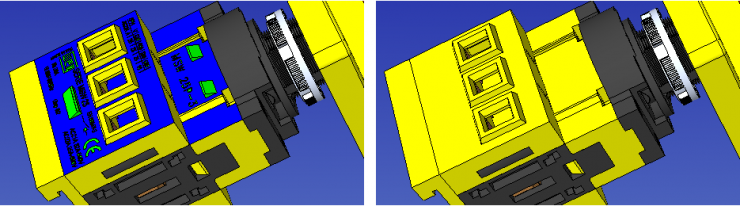

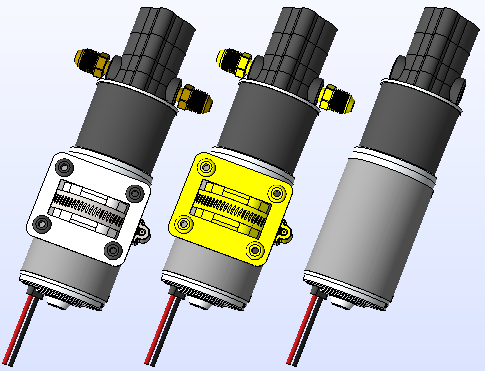

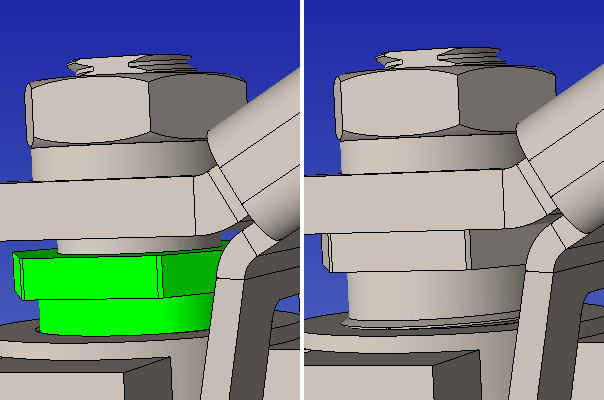

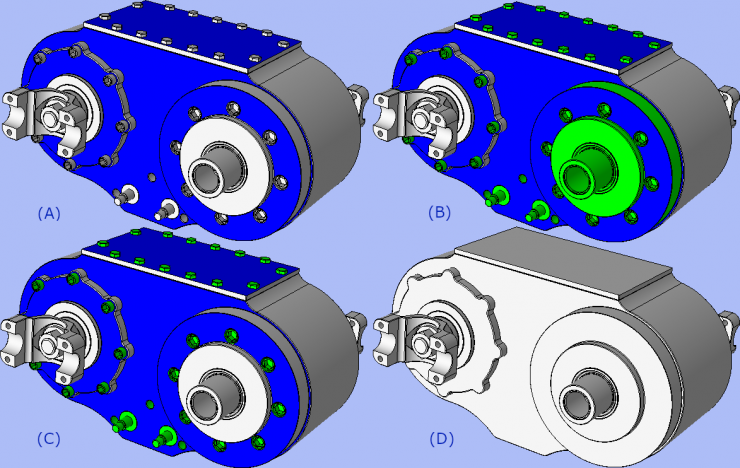

Model Simplification: Automatic Feature Detection and Removal

Often the geometric model may have more details than what are needed for the desired simulation. Through automatic detection of features, and interactive selection, the model can quickly be simplified.

(A) A few key faces for auto-detection are selected in blue.

(B) Auto-detection returns sets of connected model faces, either between the key faces or within a given key face.

(C) Since the auto-detected faces are returned in sets, it is easy to de-select groups that should remain.

(D) The rest of the features are then removed with one click, and the model is now ready for simulation.

Model Courtesy Randall E.