Thin Section Meshing

Overview

Thin Section meshing generates an extruded mesh through thin areas of a solid region. A distance can be given to define what portions of the region to considered thin, or the entire region can be meshed with thin section, depending on the geometry. Thin section meshing can be combined with other meshing capabilities, such as boundary layer meshing.

Capabilities:

- Embedded boundary layers

- Multiple source faces to multiple destination faces

- Tetrahedral, wedge, or hexahedral extrusion elements

- Automatic resolution of mismatched geometry on source/dest

- Partial extrusions in thin areas

- Automatic resolution of source/dest for stacked thin section regions

- Stepped thin sections

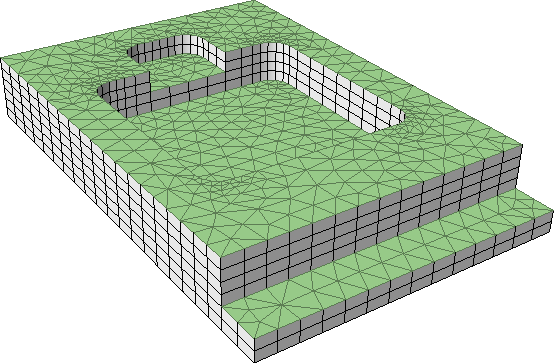

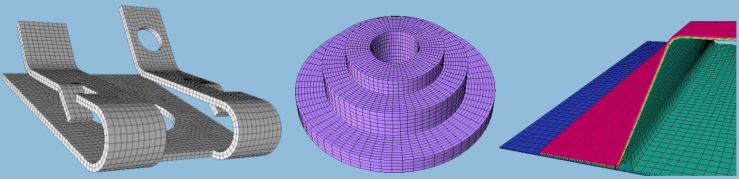

Embedded Volume Boundary Layers

This model is a single region, and it is desired to have boundary layers through the fins. The thin section mesh incorporates the boundary layer mesh specification to create a mesh that satisfies both requirements.

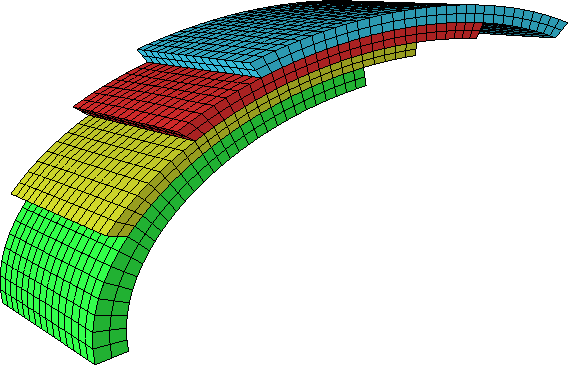

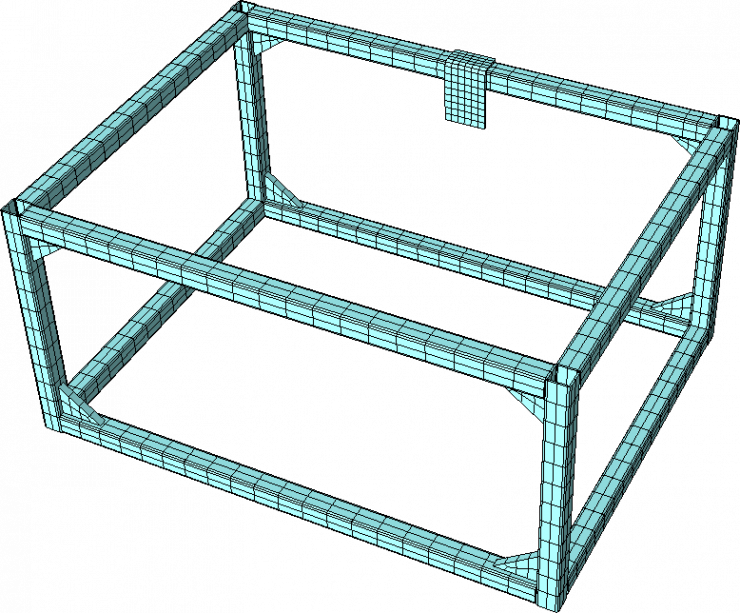

Stepped Thin Section

Thin Section Meshing can resolve steps in the geometry, as shown in this example where 6 layers were requested.

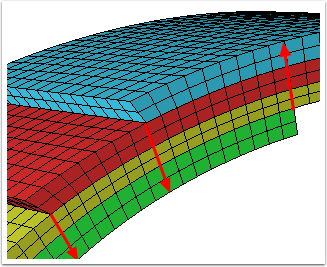

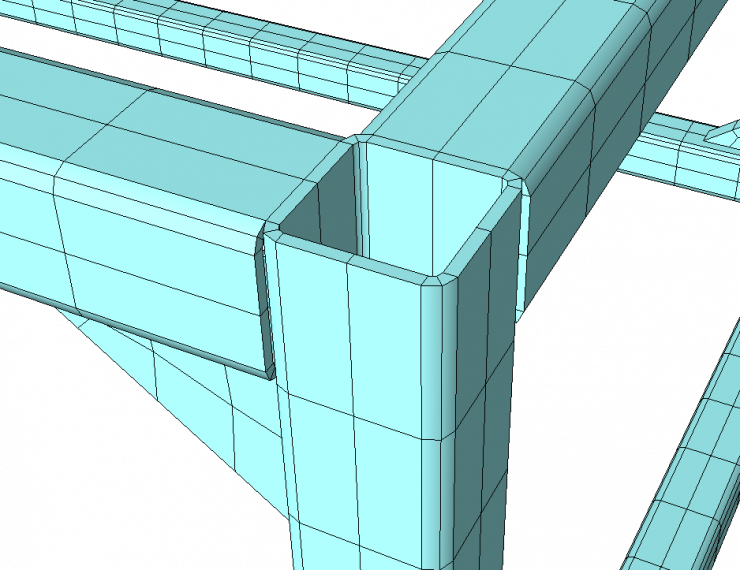

Automatic resolution of stacked thin regions

In the example shown, the imprint of one region on another is automatically resolved by thin section meshing, carrying the imprint through all necessary regions.

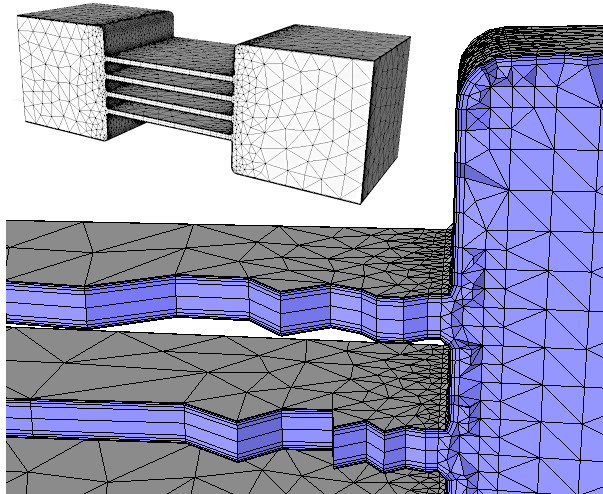

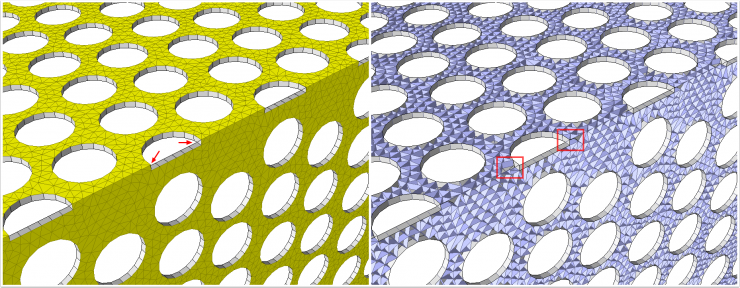

Partial Thin Section Meshing

Thin section meshing can automatically create a structured mesh wherever possible, while creating an unstructured mesh in other areas. In the example shown, thin section elements cannot be created around the holes at the bend of the sheet metal part, but can be created for the majority of the solid structure.